As a professional woodworker with over 15 years of experience, I’ve created this comprehensive board foot calculator to help fellow craftsmen, DIY enthusiasts, and lumber professionals accurately calculate wood volumes and costs. Understanding board foot measurements is essential for purchasing lumber, estimating project costs, and minimizing waste.

What is a Board Foot?

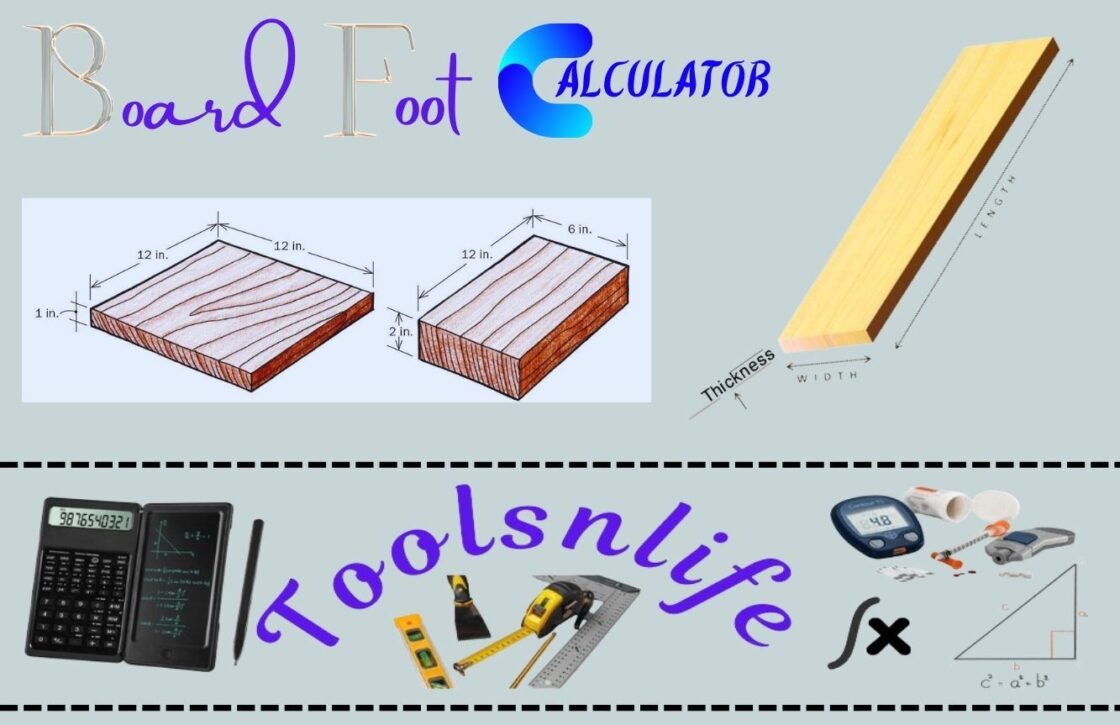

A board foot is the standard unit of measurement for lumber in the United States and Canada. One board foot equals a piece of wood that is 1 inch thick, 12 inches wide, and 12 inches long (144 cubic inches). This measurement allows for consistent pricing and quantity comparisons regardless of the specific dimensions of lumber pieces.

How to Use This Board Foot Calculator

Our calculator simplifies the process of determining board footage and costs. Follow these steps:

- Enter the number of pieces with identical dimensions

- Input thickness, width, and length measurements

- Select appropriate units for each dimension

- Add price per board foot (optional)

- Review your total board feet and cost calculations

The calculator automatically converts all measurements to inches for accurate board foot calculations, eliminating conversion errors that commonly occur during manual calculations.

Board Foot Formula

The standard formula for calculating board feet is:

Board Feet = (Thickness (inches) × Width (inches) × Length (inches)) / 144

For multiple pieces of the same dimensions, multiply the result by the number of pieces:

Total Board Feet = Number of Pieces × (Thickness × Width × Length) / 144

Our calculator automatically handles unit conversions, so you can input measurements in millimeters, centimeters, meters, feet, or yards without manual conversion.

Practical Applications and Examples

Understanding board foot calculations is essential for various woodworking and construction scenarios:

- Furniture Making: Accurately estimate lumber needs for tables, chairs, and cabinets

- Flooring Projects: Calculate materials for hardwood floor installations

- Construction: Estimate framing lumber for building projects

- Cost Estimation: Budget accurately for materials before purchasing

- Inventory Management: Track lumber usage in woodworking businesses

Real-World Example

Imagine you’re building a bookshelf that requires 5 boards, each measuring 1 inch thick, 8 inches wide, and 6 feet long. Using our calculator:

- Number of pieces: 5

- Thickness: 1 inch

- Width: 8 inches

- Length: 6 feet (72 inches)

The calculation would be: 5 × (1 × 8 × 72) / 144 = 20 board feet

If lumber costs $4 per board foot, your total material cost would be $80.

Board Foot Dimensions Visualization

This diagram illustrates the three dimensions used in board foot calculations. Understanding how thickness, width, and length contribute to the total volume helps visualize why the formula works as it does.

Board Foot Shape

Common Lumber Dimensions Reference

| Nominal Size | Actual Size (inches) | Board Feet per Foot |

|---|---|---|

| 1×4 | 0.75″ × 3.5″ | 0.292 |

| 1×6 | 0.75″ × 5.5″ | 0.458 |

| 2×4 | 1.5″ × 3.5″ | 0.583 |

| 2×6 | 1.5″ × 5.5″ | 0.917 |

| 2×8 | 1.5″ × 7.25″ | 1.208 |

| 4×4 | 3.5″ × 3.5″ | 1.361 |

Note: Nominal sizes refer to the rough dimensions before planing and drying, while actual sizes represent the finished dimensions.

Expert Tips for Accurate Calculations

- Account for Waste: Always add 10-15% to your calculated board footage to account for cutting waste and defects

- Check Moisture Content: Green lumber contains more moisture and may shrink as it dries, affecting final dimensions

- Understand Board Grading: Higher-grade boards cost more per board foot but have fewer defects and better appearance

- Consider Wood Species: Different wood species have varying densities and working properties that affect usability and cost

- Verify Measurements: Always measure your lumber personally rather than relying on nominal sizes

Frequently Asked Questions

Why is board foot measurement important?

Board foot measurement provides a standardized way to quantify lumber volume regardless of specific dimensions. This allows for consistent pricing, accurate project estimation, and fair transactions between buyers and sellers.

How does board foot differ from square foot?

Square footage measures surface area (length × width), while board footage measures volume (length × width × thickness). Board feet account for the thickness of the lumber, making it more appropriate for three-dimensional wood materials.

Can I use this calculator for metric measurements?

Yes! Our calculator automatically converts millimeters, centimeters, and meters to inches for accurate board foot calculations. Simply select the appropriate unit for each dimension.

Why are nominal lumber sizes different from actual sizes?

Nominal sizes refer to the rough-cut dimensions before planing and drying. The drying process causes shrinkage, and planing smooths the surfaces, resulting in smaller actual dimensions. Always use actual measurements for accurate calculations.

Professional Insights: Beyond Basic Calculations

As an experienced woodworker, I’ve found that mastering board foot calculations is just the beginning. Here are some advanced considerations that separate amateur projects from professional results:

- Grain Matching: When working with expensive hardwoods, factor in additional board feet for grain matching in visible areas

- Seasoning Time: Air-dried lumber requires significant storage time and space before use

- Tooling Considerations: Some exotic woods dull tools faster, increasing project costs beyond material expenses

- Board Selection: Learn to identify and avoid boards with internal stresses that may warp after cutting

Conclusion: Master Your Material Calculations

Accurate board foot calculations form the foundation of successful woodworking projects and cost-effective lumber purchases. Whether you’re a DIY enthusiast building your first shelf or a professional contractor estimating materials for a large project, this calculator provides the precision and convenience needed for optimal results.

Ready to tackle your next project with confidence? Bookmark this page for future reference, share it with fellow woodworkers, or print your calculations for your workshop. For complex projects requiring multiple wood species or custom milling, consider consulting with a lumber specialist who can provide additional guidance tailored to your specific needs.