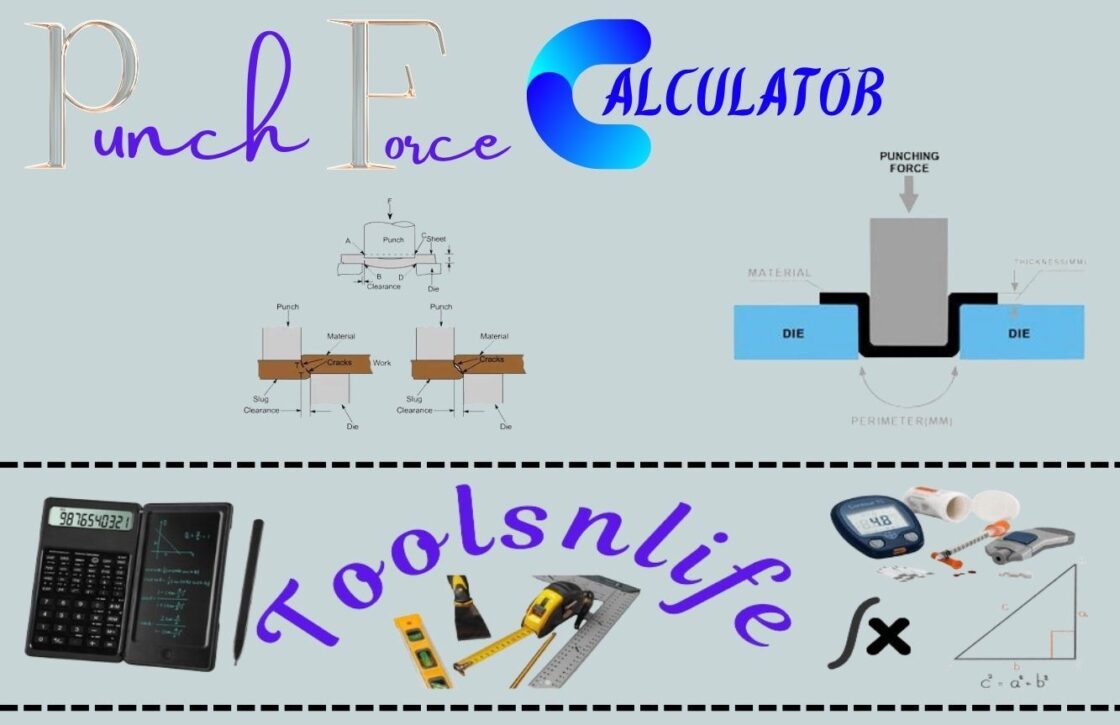

Punch Force Calculator

Calculate the required force for punching operations with precision. Our tool helps engineers and fabricators determine the exact force needed for various materials and thicknesses.

Understanding Punch Force Calculations in Metal Fabrication

Punch force calculation is a critical process in metal fabrication that determines the amount of force required to punch a hole through a material. Accurate calculations help prevent machine overloading, ensure quality results, and optimize production efficiency. As an experienced mechanical engineer with over 15 years in manufacturing, I’ve seen how proper force calculation directly impacts tool life, energy consumption, and product quality.

The Science Behind Punching Force

Punching operations involve applying sufficient force to exceed a material’s shear strength, causing fracture and separation. The fundamental formula for calculating punch force is:

F = P × t × S

Where:

- F = Punching force (in Newtons or pounds-force)

- P = Perimeter of the punched shape (in meters or inches)

- t = Material thickness (in meters or inches)

- S = Material shear strength (in Pascals or psi)

This calculation assumes ideal conditions. In practice, factors like tool wear, material variations, and cutting clearance can affect the actual force required.

Material Shear Strength Values

Different materials require different punching forces due to variations in their shear strength. Here’s a detailed comparison of the materials available in our calculator:

| Material | Shear Strength (MPa) | Shear Strength (psi) | Common Applications |

|---|---|---|---|

| A17075-T6 Aluminum | 276 | 40,000 | Aerospace components, high-stress parts |

| A16061-0 Aluminum | 103 | 15,000 | Marine fittings, architectural extrusions |

| Grey cast iron ASTM 40 | 186 | 27,000 | Engine blocks, machine bases |

| Brass UNS C28000 | 200 | 29,000 | Plumbing fixtures, musical instruments |

| A12024-T3 Aluminum | 300 | 43,500 | Aircraft structures, truck wheels |

| 3M Balsa Panel | 3 | 435 | Composite cores, lightweight structures |

| Stainless Steel 316 | 290 | 42,000 | Marine environments, chemical processing |

Practical Applications and Real-World Examples

Understanding punch force requirements is essential across various industries:

- Automotive Manufacturing: Calculating force for punching holes in chassis components

- Aerospace Engineering Determining press requirements for aluminum aircraft parts

- Construction: Planning for structural steel punching operations

- Consumer Products: Designing efficient production processes for appliance components

For example, when punching 10mm holes in 3mm thick stainless steel sheet (SS316), the perimeter would be approximately 31.4mm (π × 10mm). Using our formula: F = (0.0314m) × (0.003m) × (290 × 10^6 Pa) = 27,318 N or about 6,140 lbf.

Advanced Considerations in Punch Force Calculation

While our calculator provides excellent estimates, professional fabricators should consider these additional factors:

- Cutting Clearance: The gap between punch and die affects force requirements

- Tool Wear: Worn tools require increased punching force

- Material Variations: Actual material properties may differ from published values

- Punch Speed: Higher speeds can reduce required force through thermal effects

- Lubrication: Proper lubrication can reduce force requirements by 10-25%

Safety Factors and Practical Recommendations

Based on my experience in manufacturing engineering, I recommend these best practices:

- Add a 15-20% safety factor to calculated values to account for material variations

- Regularly calibrate equipment to ensure accurate force application

- Monitor tool wear and adjust calculations accordingly

- For critical applications, conduct physical tests to validate calculations

- Consider using tonnage monitors for real-time force measurement during production

Frequently Asked Questions

How does material thickness affect punch force?

Punch force increases linearly with material thickness. Doubling the thickness doubles the required force, assuming all other factors remain constant.

Why does perimeter length matter in punch force calculations?

The perimeter determines the total length of material being sheared. A longer perimeter means more material resistance, thus requiring greater force.

Can I use this calculator for irregular shapes?

Yes, simply calculate the total perimeter of your irregular shape and input that value. The calculator works for any shape—regular or irregular.

How accurate are the shear strength values provided?

The values are industry standards for each material. However, actual values can vary based on specific alloys, tempering processes, and manufacturing methods. For critical applications, consult your material supplier for exact specifications.

Conclusion: Optimize Your Punching Operations

Accurate punch force calculation is essential for efficient, safe, and cost-effective manufacturing operations. Our punch force calculator provides a reliable starting point for your projects, but remember to consider additional factors specific to your application. Whether you’re a seasoned engineer or a fabrication student, understanding these principles will help you achieve better results in your metalworking projects.

Ready to optimize your fabrication process? Use our calculator above for your next project, and don’t hesitate to bookmark this page for future reference. For complex applications or high-volume production, consider consulting with a materials engineer to validate your calculations.