Precision Miter Angle Calculator

Calculate perfect joint angles for woodworking, trim work, and framing projects. Our advanced calculator considers board widths and joint angles to deliver precise miter cuts every time.

Joint and Board Details

Result

Understanding Miter Angles: A Woodworker’s Essential Guide

As an experienced carpenter with over 15 years in fine woodworking and trim installation, I’ve learned that precision angle calculation separates amateur projects from professional results. Miter joints appear in countless applications—from picture frames to crown molding and furniture making.

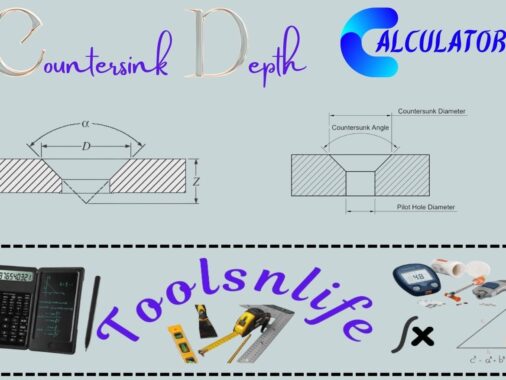

What Exactly Are Miter Angles?

Miter angles represent the cut you make on the end of a board to create a joint with another piece. Unlike butt joints where pieces meet at 90 degrees, miter joints allow for more complex angles and cleaner appearances. The mathematics behind these angles ensures that pieces fit together perfectly, regardless of the joint angle or board widths.

Practical Applications of Miter Angle Calculations

- Picture Frames: Creating perfect 45-degree corners for rectangular frames or calculating complex angles for hexagonal displays

- Crown Molding: Determining compound angles where moldings meet at inside or outside corners with different spring angles

- Furniture Making: Designing elegant joints for tables, chairs, and cabinets with non-standard angles

- Decorative Items: Crafting precise geometric patterns for wooden art pieces and decorative boxes

- Home Renovation: Installing baseboards, window trim, and door casings with professional-looking joints

Step-by-Step Guide to Using Our Calculator

Based on my years of experience, I recommend this process for best results:

- Measure the complete joint angle (θ) where the two pieces will meet

- Precisely measure the width of both boards using consistent units

- Input these values into the calculator above

- Select your preferred units for both input and results

- Read your miter angles α and β for each board

- Set your miter saw using these calculated angles

Pro Tips from a Professional Woodworker

Through countless projects, I’ve developed these techniques for flawless miter joints:

- Always account for blade kerf – The thickness of your saw blade affects the final cut

- Test cuts save materials – Make practice cuts on scrap wood from the same batch

- Consistent pressure matters – Maintain even pressure when guiding boards through the saw

- Sharp blades are essential – Dull blades tear wood fibers and compromise joint tightness

- Consider wood movement – Seasonal expansion/contraction affects joint tightness over time

Common Miter Angle Challenges and Solutions

Even experienced woodworkers encounter these issues:

- Gaps in joints: Often caused by inaccurate angle calculations or saw calibration issues

- Uneven meetings: Typically results from inconsistent board widths or imperfect cuts

- Compound angle confusion Remember that compound miters require calculations in two planes

- Measurement errors: Always measure twice and calculate once to avoid costly mistakes

Advanced Techniques for Perfect Miters

For those looking to elevate their craftsmanship, consider these advanced approaches:

Compound Miter Calculations

When working with crown molding or other applications where boards meet at both horizontal and vertical angles, you’ll need to calculate compound miters. These require adjusting both the miter and bevel angles on your saw simultaneously. While our calculator focuses on standard miter angles, understanding this complexity helps explain why precise calculations matter.

Accounting for Material Properties

Different materials behave uniquely during cutting:

- Hardwoods: Typically hold sharper edges but may require slower cutting speeds

- Softwoods: More prone to compression during cutting, potentially affecting joint tightness

- MDF and composites Tend to produce cleaner cuts but generate more dust

- Plastics and synthetics: Often require specialized blades to prevent melting or chipping

Safety Considerations

As a safety-conscious woodworker, I must emphasize these critical precautions:

- Always wear safety glasses and hearing protection when operating power tools

- Keep hands at least 6 inches from the blade at all times

- Use push sticks for narrow cuts where fingers might approach the blade

- Ensure your workspace is well-lit and free of obstructions

- Regularly maintain your tools to ensure they’re in optimal working condition

- Never wear loose clothing or jewelry that could catch in machinery

Frequently Asked Questions

Why do I need different angles for different board widths?

When boards of different widths meet at an angle, the geometry requires different miter cuts to create a seamless joint. The wider board typically requires a slightly shallower angle while the narrower board needs a steeper cut to match the joint angle properly.

Can I use this calculator for crown molding?

Our calculator works excellently for standard miter joints. However, crown molding often requires compound miter calculations that account for both the wall angle and the spring angle of the molding itself. For complex crown molding projects, you may need specialized compound angle calculators.

How accurate are these calculations?

The mathematical calculations are precise to the degree of accuracy of your inputs. However, practical results depend on your measuring accuracy, tool calibration, and cutting technique. I always recommend adding a half-degree for wood compression in tight-fitting joints.

Conclusion: Elevate Your Woodworking with Precision

Mastering miter angles transforms your woodworking from amateur to professional quality. This calculator, based on proven mathematical principles and refined through years of practical application, provides the precision necessary for flawless joints. Whether you’re framing a cherished photograph, installing elegant crown molding, or building heirloom furniture, accurate angle calculation ensures results you’ll be proud of for years to come.

Ready to transform your woodworking projects? Bookmark this page for future reference, share it with your woodworking friends, and don’t hesitate to reach out if you have specific questions about your project. With the right calculations and techniques, you’ll create joints so perfect they appear to be crafted from a single piece of wood.