Welcome to our comprehensive K-Factor Calculator – an essential tool for metal fabricators, engineers, and designers working with sheet metal bending operations. This calculator helps you accurately determine the K-factor, bend allowance, and neutral axis position for your bending projects.

What is the K-Factor in Sheet Metal Bending?

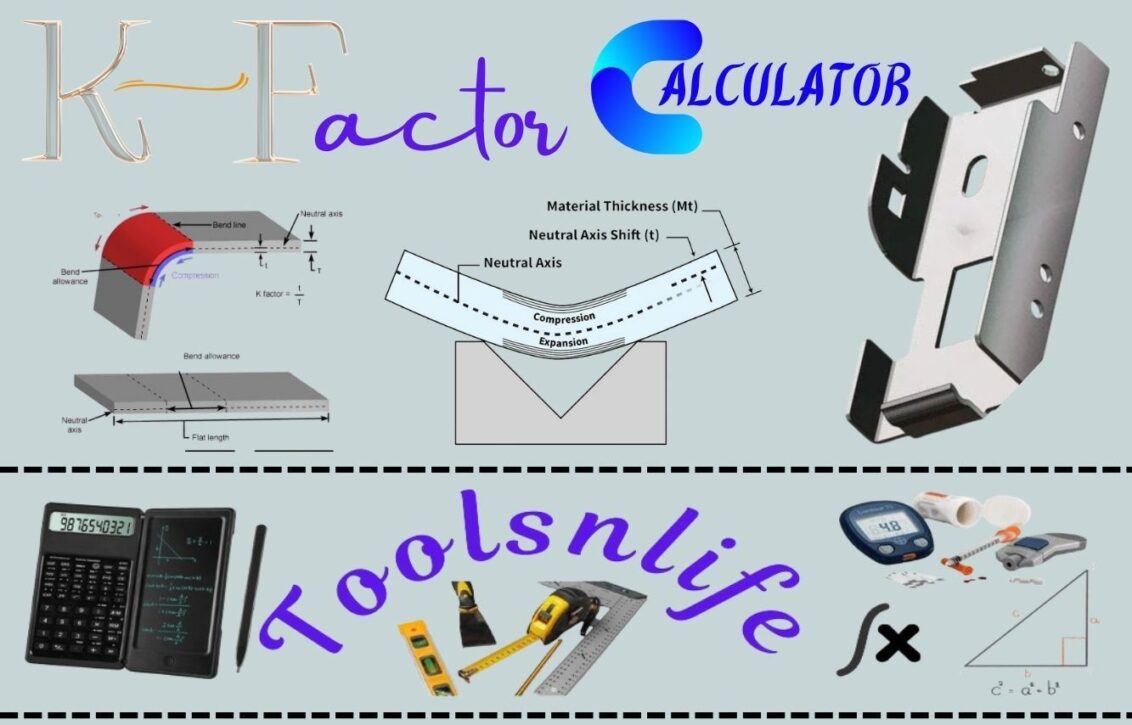

The K-factor represents the ratio of the neutral axis location to the material thickness. This crucial parameter helps determine how much material is needed for a bend and where the bend will occur without deformation. In practical terms, the K-factor accounts for the material’s stretching and compression during bending operations.

Typically, K-factor values range between 0.3 and 0.5, with 0.44 being a common default value for most materials. However, the exact value depends on multiple factors including material type, bending method, and tooling specifications.

How to Use Our K-Factor Calculator

Our calculator simplifies the complex calculations involved in sheet metal bending. Simply follow these steps:

- Enter the material thickness (T) with the appropriate unit

- Input the inside radius (Rᵢ) of your bend

- Specify the bend angle (θ) in degrees, radians, or gons

- The calculator will automatically compute the bend allowance, K-factor, and neutral axis position

You can work with various measurement units and the calculator will handle all conversions automatically, ensuring accurate results regardless of your preferred unit system.

Understanding the Calculations

The formulas powering our calculator are based on established engineering principles:

- Bend Allowance (BA) = π × (Rᵢ + T) × θ / 180

- K-Factor (K) = Rᵢ / (Rᵢ + T)

- Neutral Axis Location (t) = K × T

These calculations help determine the exact length of material required for a bend, ensuring precision in your manufacturing process and reducing material waste.

Practical Applications of K-Factor Calculations

Accurate K-factor calculations are essential for:

- Sheet Metal Fabrication: Precisely calculating flat pattern dimensions

- CAD/CAM Programming: Ensuring accurate digital models match physical results

- Quality Control: Maintaining consistency across production runs

- Cost Estimation: Accurately predicting material requirements

- Process Optimization: Fine-tuning bending operations for efficiency

Factors Affecting K-Factor Values

Several variables influence the K-factor in practical applications:

- Material Type: Different metals (steel, aluminum, copper) have different bending characteristics

- Material Hardness: Annealed vs. hardened materials behave differently during bending

- Bending Method: Air bending, bottoming, and coining produce different results

- Tooling Specifications: Punch and die configurations affect the bend

- Bend Direction: Bending with or across the material grain affects results

Expert Tips for Accurate K-Factor Determination

Based on years of metal fabrication experience:

- Always validate calculated K-factors with test bends when working with new materials

- Document successful K-factor values for specific materials and thicknesses for future reference

- Remember that K-factor can vary slightly between batches of the same material

- For critical applications, consider conducting a bend deduction test to verify calculations

- When in doubt, consult with material suppliers for recommended K-factor values

Common K-Factor Values by Material

While our calculator provides precise values, these general guidelines can help with estimation:

- Mild Steel: 0.40-0.45

- Stainless Steel: 0.42-0.48

- Aluminum: 0.38-0.44

- Copper: 0.35-0.42

- Brass: 0.37-0.43

Remember that these are approximations – always calculate the exact K-factor for your specific application using our calculator or physical testing.

Troubleshooting Common Bending Issues

If your actual results differ from calculations, consider these potential issues:

- Springback: Material elasticity causing the bend to open after pressure release

- Material Variation: Inconsistent material properties affecting bend consistency

- Tool Wear: Worn punches or dies producing inconsistent results

- Incorrect Measurements: Ensure accurate measurement of inside radius and material thickness

Advanced Applications: Beyond Basic K-Factor Calculations

For complex bending operations, consider these advanced factors:

- Multiple Bends: Account for interaction between adjacent bends

- Complex Geometries: Special calculations for unusual bend shapes

- Material Anisotropy: Direction-dependent material properties

- Temperature Effects: How environmental conditions affect bending characteristics

Industry Standards and References

Our calculator aligns with established industry standards including:

- ASME Y14.5 – Dimensioning and Tolerancing

- ISO 2768 – General tolerances

- Manufacturing industry best practices for sheet metal fabrication

Conclusion: Precision in Metal Bending

Accurate K-factor calculation is fundamental to successful sheet metal fabrication. Our calculator provides instant, precise results that help eliminate guesswork and reduce material waste. Whether you’re a seasoned fabricator or new to metal bending, this tool will help you achieve consistent, reliable results in your bending operations.

Ready to optimize your bending process? Use our K-Factor calculator for your next project and experience the difference precision engineering makes. Share your results with colleagues, print calculations for your workshop, or refresh to start new calculations. For complex projects or unusual materials, consider conducting physical test bends to validate your calculations.